Green hydrogen is hydrogen obtained by splitting water from renewable energy sources such as solar and wind energy, and when it is burned, it produces only water, achieving zero carbon dioxide emissions from the source, so it has earned the excellent title of "zero-carbon hydrogen".

Although hydrogen energy is a clean and sustainable new energy source that does not emit carbon dioxide in the process of releasing energy, the current process of producing hydrogen energy is not 100% "zero-carbon". For example, the production of gray hydrogen and blue hydrogen, the other two brothers of green hydrogen, is divided into three categories: gray hydrogen, blue hydrogen, and green hydrogen, according to the source of production and the emissions in the production process.

Grey hydrogen is produced by the combustion of fossil fuels such as oil, natural gas, coal, etc., and although the manufacturing process is low-cost, gray hydrogen is the least popular among the "three brothers" due to the large amount of carbon dioxide emitted from the whole process.

Blue hydrogen is an "upgraded" version of grey hydrogen, made from fossil fuels such as coal or natural gas. While natural gas is also a fossil fuel and produces greenhouse gases when producing blue hydrogen, advanced technologies such as carbon capture, storage and utilization can capture greenhouse gases and ultimately enable low-emission production with reduced environmental impact. Grey hydrogen is used as a fuel for transportation, which actually emits more than direct diesel and gasoline. Compared with grey hydrogen obtained from industrial raw materials, green hydrogen is more pure and has fewer impurities, making it more suitable for fuel cell vehicles and promoting the clean transformation of the transportation sector.

In the chemical industry, hydrogen is often used as a feedstock for the production of ammonia methanol and other chemicals. The emergence of green hydrogen not only contributes to the deep decarbonization of the ammonia production process, but also replaces natural gas and coal for the production of green methanol, reducing carbon emissions in the production of chemicals.

In addition, asphalt can also solve the problem of excess renewable energy generation, and reuse curtailment of wind, solar and water, thereby increasing the utilization rate of renewable energy.

In 2022, the proton exchange membrane water electrolysis hydrogen production system of the Dachen Island Hydrogen Energy Comprehensive Utilization Demonstration Project in Zhejiang Province successfully achieved hydrogen production. Tourism and aquaculture are the island's two pillar industries, and the "green hydrogen ™ integrated energy system can supply electricity and heat for homestays, hotels, villas, etc." The oxygen produced in the hydrogen production process can be provided to yellow croaker farmers, giving full play to the value of hydrogen production by-products and providing impetus for the development of the local aquaculture industry. Green hydrogen is so good, isn't its appearance fee very "expensive"? The amount of electricity required to produce hydrogen by electrolysis is huge, and it takes about 50 kilowatt-hours of electricity to produce one kilogram of hydrogen, which is prohibitively expensive. However, with the further maturity of wind power, tidal power, solar power generation and other technologies, the production cost of green electricity has been reduced, which indirectly reduces the production cost of green hydrogen.

Green hydrogen is no longer "unattainable", and the production of hydrogen through electrolysis of water through photovoltaic power generation not only achieves no carbon emissions in the production process, but also achieves zero carbon emissions in the use process, achieving truly double the clean. It is believed that with the further maturity of future technologies, "green hydrogen" will become one of the important and major new energy sources in the future, and contribute more to the realization of the dual carbon goals.

l Durable Construction: Made from galvanized aluminum-zinc, achieving IP3X protection and reliable anti-misoperation features.

When tomorrow turns in today, yesterday, and someday that no more important in your memory, we suddenly realize that we are pushed forward by time.This is not a train in still in which you may feel forward when another train goes by.It is the truth that we've all grown up.And we become different.

l Durable Construction: Made from galvanized aluminum-zinc, achieving IP3X protection and reliable anti-misoperation features.

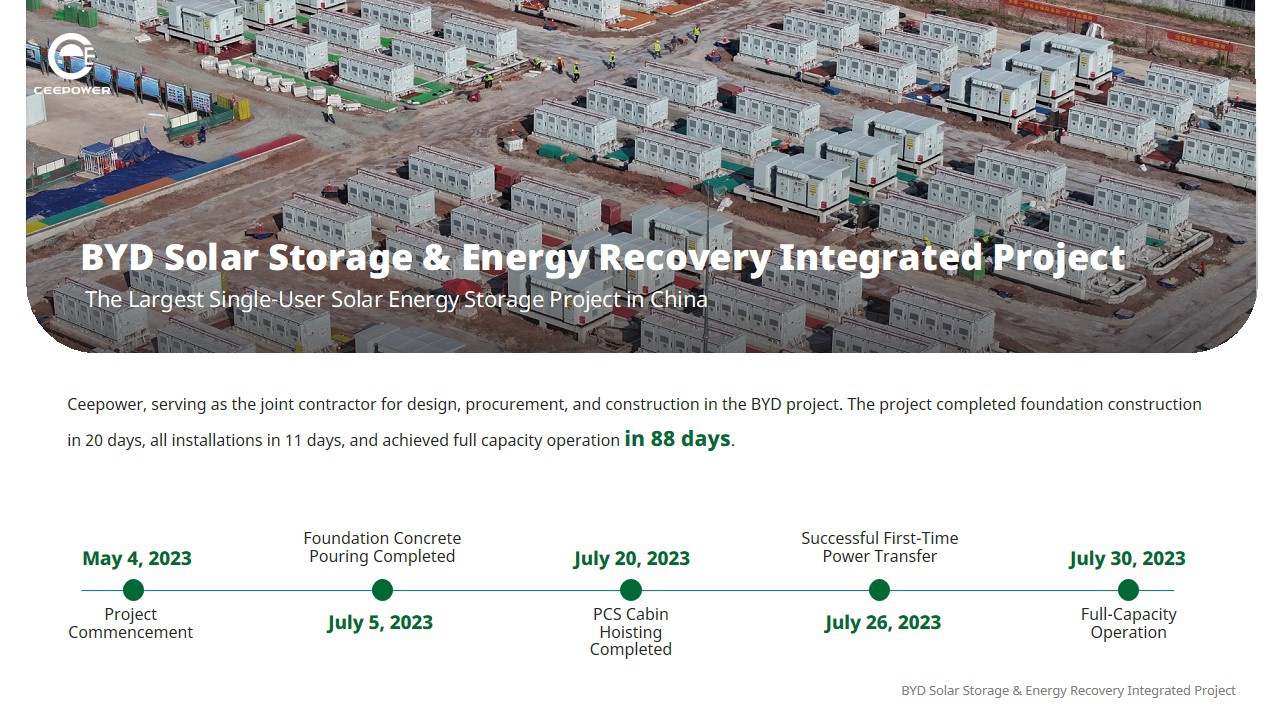

At 11:08 PM on July 30, 2024, Ceepower successfully completed the commissioning of the BYD Solar Energy Storage & Recovery Integration Project in Chongqing, achieving full-capacity operation.

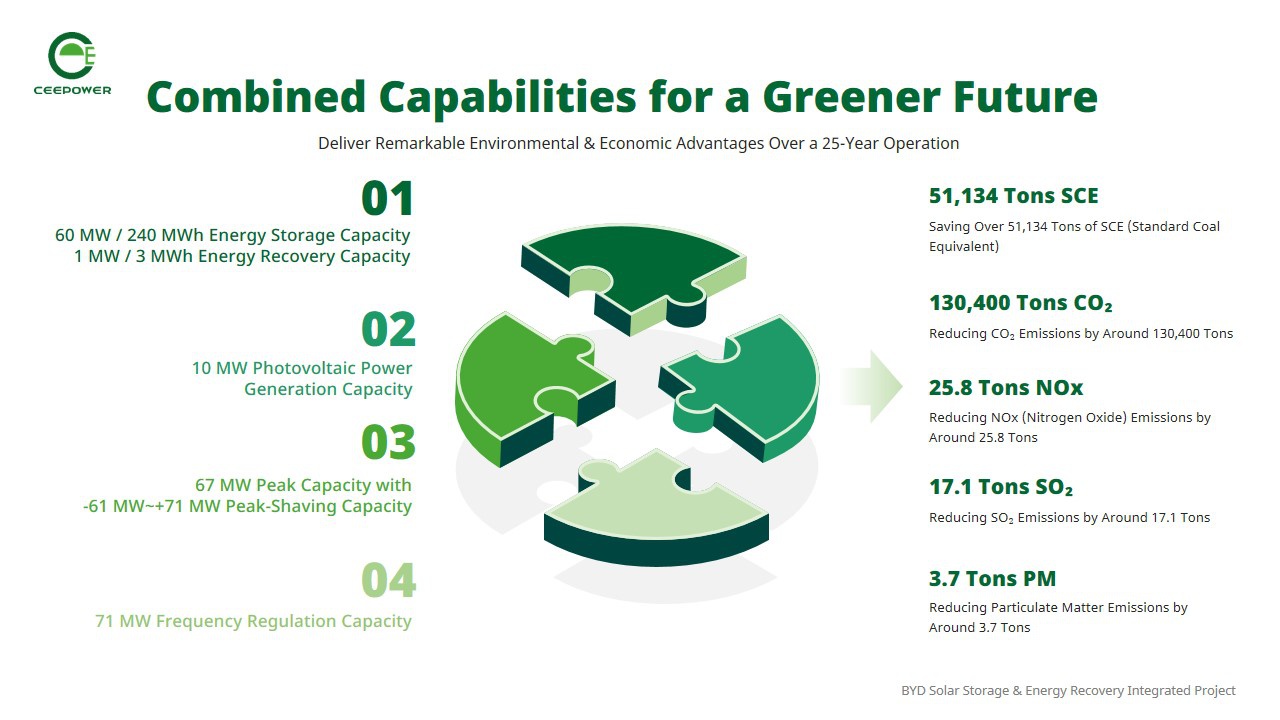

This project, a key peak-load power source for Chongqing’s summer energy supply, is the largest single-user solar+energy storage project in the country. It consists of a 60 MW/240 MWh energy storage system, 10 MW of photovoltaic power capacity, and an energy recovery system, with a peak-load capacity of 67 MW. As a core component of the Bishi Integrated Smart Zero-Carbon Power Plant, the project will enable smart energy management, aggregating various resources such as generation, consumption, and storage to ensure reliable power supply during peak demand periods.

Accelerating Construction to Meet Energy Demands

The BYD Project was launched as part of a commitment to support Chongqing's peak-load electricity needs. With a tight timeline to increase peak-load capacity before summer, the project focused on speed and efficiency. Ceepower, as the joint design, procurement, and construction partner, recognized the importance and urgency of the project. Leveraging its technological innovation strengths, Ceepower worked alongside all project stakeholders to implement a rigorous construction schedule. The team adopted a "5+2" and "day-and-night" work strategy, optimizing construction processes to achieve rapid results: the civil construction was completed in 20 days, the installation in 11 days, and the full-capacity operation in just 88 days.

Overcoming Challenges to Ensure Successful Completion

Throughout the project, Ceepower maintained a strong focus on engineering quality, safety, schedule, and cost control. Drawing on its capabilities in power equipment R&D, comprehensive energy services, and technological innovation, Ceepower collaborated closely with partners to optimize designs and enhance project management. Despite challenges such as tight deadlines, heavy workloads, high temperatures, and rainy season disruptions, the team ensured the project was delivered ahead of schedule, meeting quality and performance targets. This successful completion of the BYD Project was a significant achievement, showcasing Ceepower’s ability to turn ambitious goals into reality.

Paving the Way for Future Energy Storage Solutions

The completion of the BYD Project represents both a major challenge and a powerful validation of Ceepower’s capabilities. In the rapidly developing energy storage sector, Ceepower is committed to advancing core technologies for large-capacity, long-cycle, low-cost, and high-safety energy storage systems. These technologies meet the growing demand for "new energy+energy storage" applications, providing integrated clean energy solutions that contribute to grid stability, support corporate green transitions, and offer reliable options for safe electricity use.

This project marks a new chapter for Ceepower in the energy storage field, setting a benchmark for future developments and collaborations, and reinforcing Ceepower's leadership in the clean energy transition.

On July 28, 2024, Ceepower and MEMF Electrical Industries Co. (MEMF) signed a strategic cooperation agreement at Ceepower’s headquarters in Fuzhou. The ceremony was attended by Ceepower President, Ms. Chen Manhong, and MEMF's Executive Vice President, Mr. Ahmed A. Al-Mohaimeed, along with other senior leaders from both companies. This partnership marks a significant step in enhancing cooperation in the smart distribution and cable accessory sectors.

MEMF is a leading electrical equipment manufacturer in Saudi Arabia with over 25 years of experience in the GCC region. It has been a trusted partner of Ceepower since 2006, focusing on medium-voltage cable accessories. The new agreement deepens this long-standing collaboration, shifting from product supply to joint research and technological innovation, in line with Saudi Arabia’s Vision 2030 and its energy diversification goals.

The two companies will focus on areas such as equipment supply, technical support, and supply chain optimization over the next five years. This partnership will help drive the region’s energy transformation and reinforce Ceepower’s growing international presence. During their visit to Ceepower’s production facilities, MEMF’s delegation was impressed by Ceepower’s innovations in smart electrical solutions and its focus on sustainable energy development.

This strategic agreement not only strengthens Ceepower’s footprint in the Middle East but also positions both companies to contribute significantly to the region’s energy transition, providing innovative solutions in line with global sustainability goals.

Ceepower attended the inaugural China-Nigeria Economic and Trade Cooperation Forum, held during the 2024 China-Africa Forum in Beijing, which marked the upgrading of China-Nigeria relations to a comprehensive strategic partnership. The forum facilitated discussions between Ceepower, Nigerian government officials, and businesses on key areas of collaboration, including power, renewable energy, and smart technologies.

The event, themed “Precise Matching,” aimed to strengthen ties between Chinese businesses and Nigerian state governments. Nigeria, as Africa’s largest economy and China’s primary export market in the region, presents significant opportunities for trade and investment.

At the forum, Ceepower engaged in targeted trade talks with Nigerian officials, focusing on key sectors such as energy storage, smart grid solutions, and rail transport. The company’s participation underscores its commitment to expanding in the African market, leveraging its extensive industry expertise and customer base.

Ceepower aims to use this collaboration to explore new opportunities in Nigeria and contribute to the global energy transition through its integrated solutions in cable accessories, smart distribution equipment, and energy storage. This marks a significant step in Ceepower’s strategy to expand its footprint in the international market, especially in Africa.

On September 29th, the Chongqing-Yibin section of the Chongqing-Kunming High-Speed Railway officially opened. Ceepower’s subsidiary, Wuhan Wuchang Electric Control Co., Ltd., supplied 126 prefabricated substations, ensuring reliable power along the 192-kilometer route.

Designed for speeds of up to 350 km/h, this section significantly shortens travel times between major cities, reducing the journey from Chongqing to Luzhou East to just 26 minutes, and to Yibin Station in as little as 48 minutes. It enhances regional connectivity and supports the development of the Chengdu-Chongqing economic circle and the Yangtze River Economic Belt.

Ceepower’s modular, compact substations are tailored to Sichuan’s complex terrain, providing a stable power supply for the safe operation of this critical rail line.

Committed to innovation and excellence, Ceepower continues to support the expansion of China’s rail infrastructure.

Ceepower has recently made notable advancements in the international rail sector, securing contracts worth over 60 million CNY. Key projects include the Masi Railway in Guinea, the Masi Railway Branch with Rio Tinto, and the East Coast Rail Link (ECRL) in Malaysia. These contracts emphasize the growing global presence of Ceepower’s core products, including prefabricated substations and high- and low-voltage switchgear from its subsidiary, Wuhan Electric Controlgear Co., Ltd.

Transforming Guinea’s Rail Infrastructure

The Masi Railway, spanning 552.5 kilometers, will be the first dual-track heavy-duty railway, equipped with a satellite-based signaling system. This project aims to enhance transportation efficiency and stimulate regional economic growth through improved mineral resource development. Ceepower’s success in this contract signifies its strategic entry into the African rail market.

Connecting Malaysia with the East Coast Rail Link

The ECRL connects Kota Bharu to Port Klang over 665 kilometers, serving as a critical infrastructure project under the Belt and Road Initiative. It will improve transport links between Malaysia’s east and west coasts, fostering balanced regional development. Wuchang Electric Control will supply essential electrical equipment for this project, further solidifying Ceepower’s reputation for quality and reliability in the global market.

Strengthening Global Operations

With a commitment to advanced research and development, Ceepower is set to expand its offerings in cable accessories, photovoltaic storage solutions, and other energy products. This aligns with its strategy to actively participate in the global energy transition, driving sustainable development through innovative solutions.

Ceepower’s recent achievements in the rail sector not only enhance its international footprint but also demonstrate its dedication to delivering high-quality solutions that meet the demands of global infrastructure projects. The company is focused on contributing to a sustainable future through strategic expansion and innovation in the energy sector.

The Shenzhen-Zhongshan Channel is a groundbreaking infrastructure project that spans approximately 24 kilometers, connecting the east and west banks of the Pearl River. This major undertaking combines bridges, islands, tunnels, and underwater connections, presenting complex construction challenges and demanding high technical standards.

Reliable power supply is essential for the project's success. As a trusted supplier for the Southern Power Grid, Ceepower is providing advanced ring main units to support this world-class engineering endeavor.

Quality Service for Major Projects

Ceepower's ring main units are vital for maintaining stable electricity supply. In this project, they will handle power distribution, protection, and control within an intelligent 10 kV distribution switch station. Utilizing advanced automation technology, these cabinets ensure rapid fault recovery times in the millisecond range. To further ensure smooth operation, Ceepower will provide comprehensive technical support and after-sales services.

Enhancing Distribution Network Efficiency

Designed with advanced features, Ceepower’s ring main units integrate high-voltage switching, protection, control, measurement, and communication functions. Their compact design and reliability ensure stable performance in challenging environments.

In the future, Ceepower will continue to focus on the power industry, dedicated to providing high-quality power equipment and services for more major engineering projects, thereby contributing significantly to the country's infrastructure development and economic and social progress.